Capabilities

ADAPT Research Equipment and Capabilities

ADAPT additive manufacturing equipment is divided between the Additive Manufacturing, Mechanics, Materials, and Design (AM3D) and the Materials and Manufacturing Labs, located in the CoorsTek Center for Applied Sciences and Engineering, and the Advanced Manufacturing Teaching Lab, located in Brown Hall. ADAPT researchers also use mechanical testing and characterization equipment within the Mines’ Shared Instrumentation Facility (SIF).

Additive Manufacturing

3D Systems DMP Flex 350

The 3D Systems DMP Flex 350 is an industrial-grade metal laser powder bed fusion (LPBF) printer with a 500 W laser, minimum feature size of 100 µm, and layer thicknesses from 10-100 µm. The printer is also factory equipped with in situ process monitoring for detecting powder recoating issues and melt pool data linked to porosity.

Materials: steel, aluminum, titanium, Ni-based, CoCR

Build envelope: 275x275x420 mm

FormAlloy X2

The FormAlloy X2 is a blown powder directed energy deposition (DED) metal printer with a 1 kW laser and 4 powder feeding stations. The powder feeding stations allow for alloy development and graded alloys through continuously variable composition. The printer is also factory equipped with in situ melt pool monitoring and analysis software that allows for closed loop feedback control.

Materials: Broad range of powders including steel and alloys of Al, Ti, Ni, and Cu

Build envelope: 250x250x300 mm

Desktop Metal Studio System

The Desktop Metal Studio System uses Bound Metal Deposition™ to produce metal parts. The printing process is similar to polymer extrusion printers except with a metal powder that is held together with a wax and polymer binder. Printed parts go through a two-step debinding and sintering process to produce the final metal part. Materials include stainless steels, tool steels, titanium, and copper. It has a print volume of 300 x 200 x 200 mm, minimum layer height of 0.050 mm, and minimum feature size of 0.50 mm.

Materials: stainless steels, tool steels, titanium, and copper.

Build envelope: 300 x 200 x 200 mm, minimum layer height of 0.050 mm, and minimum feature size of 0.50 mm.

Lithoz CeraFab 7500

The CeraFab 7500 facilitates the production of high-performance ceramics that possess equal or better material properties as those achieved using conventional manufacturing processes. By eliminating the need for tools and by keeping the level of material consumption throughout the production process to a minimum, it is possible to economically manufacture prototypes and small batches of high-performance ceramic parts. Layer thickness is 10–100 μm.

Materials: aluminum oxide, zirconium oxide, silicon nitride. Materials for special applications include tricalcium phosphate, hydroxyapatite, silica-based materials. See other materials that Lithoz has processed using its LCM technology.

Build envelope: 76 × 43 × 170 mm.

3D Systems ProJet 6000

The 3D Systems ProJet 6000 is an industrial-grade high resolution stereo lithography (SLA) printer that offers a wide variety of resins with cured properties that meet or exceed their standard engineering counterparts. The ProJet 6000 can also print transparent parts.

The 3D Systems ProJet 6000 is an industrial-grade high resolution stereo lithography (SLA) printer that offers a wide variety of resins with cured properties that meet or exceed their standard engineering counterparts. The ProJet 6000 can also print transparent parts.

Materials: photocurable resins

Build envelope: 250 x 250 x 250 mm and feature reproducibility as low as 0.050 mm.

HP MultiJet Fusion 580

The HP MultiJet Fusion 580 is a multi-agent binder jetting system capable of full-color functional parts in nylon (PA 12). It provides voxel-level control of material appearance and properties and can produce parts a up to 10x the speed of other traditional polymer additive manufacturing systems.

The HP MultiJet Fusion 580 is a multi-agent binder jetting system capable of full-color functional parts in nylon (PA 12). It provides voxel-level control of material appearance and properties and can produce parts a up to 10x the speed of other traditional polymer additive manufacturing systems.

Materials: Nylon (polyamide 12)

Build envelope: 190 × 332 × 248 mm

Markforged Mark Two

The Markforg ed Mark Two is a high-end desktop material extrusion printer with a variety of easily adjustable parameters, making it well suited for everything from educational to industrial applications. It can deposit layers 0.100–0.200 mm thick.

ed Mark Two is a high-end desktop material extrusion printer with a variety of easily adjustable parameters, making it well suited for everything from educational to industrial applications. It can deposit layers 0.100–0.200 mm thick.

Materials: chopped carbon fiber reinforced nylon (Onyx) with the option of continuous fiber reinforcement (carbon fiber, Kevlar, fiber glass, and high-temperature, high-strength fiberglass), which allows for selective and local enhancement of mechanical properties.

Build envelope: 320 × 132 × 154 mm

Stratasys F170

The Stratasys F170 is an industrial-grade material extrusion printer that can produce service-ready components as well as low-cost rapid prototypes. It is capable of printing PLA, ABS, ASA, TPU 92A (a durable elastomer), and soluble support material. It deposits layers 0.127–0.330 mm thick and has 0.200 mm overall part accuracy.

The Stratasys F170 is an industrial-grade material extrusion printer that can produce service-ready components as well as low-cost rapid prototypes. It is capable of printing PLA, ABS, ASA, TPU 92A (a durable elastomer), and soluble support material. It deposits layers 0.127–0.330 mm thick and has 0.200 mm overall part accuracy.

Materials: PLA, ABS, ASA, TPU 92A (a durable elastomer), and soluble support material

Build envelope: 254 × 254 × 254 mm

Stratasys Objet Eden260VS

The Stratasys Objet Eden260VS is a high-resolution material jetting printer compatible with a broad range of proprietary UV-curable resins. The spectrum of cured resin properties include thermally stable, high strength, high stiffness, high ductility, rubber-like, variable color, and easily removable support material. It can deposit layers with a thickness as low as 0.016 mm and feature accuracy as low as 0.020 mm.

The Stratasys Objet Eden260VS is a high-resolution material jetting printer compatible with a broad range of proprietary UV-curable resins. The spectrum of cured resin properties include thermally stable, high strength, high stiffness, high ductility, rubber-like, variable color, and easily removable support material. It can deposit layers with a thickness as low as 0.016 mm and feature accuracy as low as 0.020 mm.

Materials: UV-curable resins

Build Envelope: 255 × 252 × 200 mm

Direct Ink Write (DIW) 3D Printer

The student-built direct ink write (DIW) 3D printer is designed for testing viscous additive manufacturing materials and studying the effects of process parameters on the additive manufacturability of these materials. The printer is equipped with several pressurized dispensing heads that allow it to print a variety of materials, including two-part (2K) mixtures, ranging in viscosity from 1cP to greater than 150,000 cP. Customizable print parameters include dispensing and slicing strategies, machine feeds and speeds, dispensing pressure, filament/nozzle diameter, and material curing methods. The machine also incorporates print monitoring equipment, including thermal and high-speed cameras.

The student-built direct ink write (DIW) 3D printer is designed for testing viscous additive manufacturing materials and studying the effects of process parameters on the additive manufacturability of these materials. The printer is equipped with several pressurized dispensing heads that allow it to print a variety of materials, including two-part (2K) mixtures, ranging in viscosity from 1cP to greater than 150,000 cP. Customizable print parameters include dispensing and slicing strategies, machine feeds and speeds, dispensing pressure, filament/nozzle diameter, and material curing methods. The machine also incorporates print monitoring equipment, including thermal and high-speed cameras.

Materials: Various viscous materials

Build Envelope: 500 × 300 × 100 mm, with a minimum layer height of 0.040 mm

Laser-Wire Directed Energy Deposition (DED) System

The laser-wire directed energy deposition (DED) system consists of a 3-axis CNC machining center equipped with a 4 kW IPG ytterbium fiber laser with IPG Weld D30 series welding head and a Miller 70 Series wire feeder. The fiber laser operates in continuous wave mode with a wavelength of 1070 nm. The laser-wire DED system has three optris infrared pyrometers and an optris thermal camera, which can travel in line with the laser head, for process monitoring. Versatility in shielding gas and process monitoring set-up possible with CNC machining center and customization of fixture. Traditional laser welding possible as well.

Materials: Traditional welding wire– steel, aluminum, nickel

Build Envelope: 4 x 3 x 2 ft

EOS M 290

The EOS M 290 is an industrial-grade metal laser powder bed fusion (LPBF) printer with a 400 W laser, minimum feature size of 100 µm, and layer thicknesses from 20-80 µm. The printer is also factory equipped with in situ process monitoring for detecting powder recoating issues and melt pool data linked to porosity.

Materials: steel, aluminum, titanium, nickel, cobalt chrome, copper

Build envelope: 250x250x325 mm

Wire Arc Additive Manufacturing Cobot

Our wire-arc additive manufacturing equipment achieves motion control is through a Universal Robots UR10e collaborative robot (cobot). The cobot can be programmed online by teaching points and it can accept Gcode from the open source tool path planning software Cura. The heat source is a Fronius TPSi400 with cold metal transfer (CMT) capability.

MTS 370.25 Uniaxial Servohydraulic Load Frame with Environmental Chamber

The MTS 370.25 provides high-fidelity uniaxial mechanical data on additively manufactured standard tensile test specimens for larger, structural materials. When combined with the composition- and orientation-related degrees of freedom available in metals 3D printers, this load frame provides an invaluable comparison of tension, compression and fatigue test data for AM parts with the extensive test data available for traditionally manufactured parts. It is also equipped with an MTS environmental chamber for low and high temperature testing from –129 to 315 °C.

The MTS 370.25 provides high-fidelity uniaxial mechanical data on additively manufactured standard tensile test specimens for larger, structural materials. When combined with the composition- and orientation-related degrees of freedom available in metals 3D printers, this load frame provides an invaluable comparison of tension, compression and fatigue test data for AM parts with the extensive test data available for traditionally manufactured parts. It is also equipped with an MTS environmental chamber for low and high temperature testing from –129 to 315 °C.

Features:

-

- 250 kN load capacity

- Environmental chamber for high and low temperature testing

- Alignment fixture ensures compliance with ASTM E1012, GES400 (NADCAP), GE450 and ISOTC 164SC5WG11

MTS 370.10 Uniaxial Servohydraulic Load Frame

The MTS 370.10 provides high-fidelity uniaxial mechanical data on additively manufactured standard tensile test specimens for larger, structural materials. When combined with the composition- and orientation-related degrees of freedom available in metals 3D printers, this load frame provides an invaluable comparison of tension, compression and fatigue test data for AM parts with the extensive test data available for traditionally manufactured parts.

The MTS 370.10 provides high-fidelity uniaxial mechanical data on additively manufactured standard tensile test specimens for larger, structural materials. When combined with the composition- and orientation-related degrees of freedom available in metals 3D printers, this load frame provides an invaluable comparison of tension, compression and fatigue test data for AM parts with the extensive test data available for traditionally manufactured parts.

Features:

- 100 kN load capacity

- Cooled grips for in situ, high-temperature mechanical testing

- Alignment fixture ensures compliance with ASTM E1012, GES400 (NADCAP), GE450 and ISOTC 164SC5WG11

MARK-10 Electromechanical Load Frame

The Mark 10 electromechanical load frame is a small, benchtop load frame that is easily configurable for tensile, compressive and bending testing of samples. It is well suited to characterize 3D-printed compression cylinders imaged with the Zeiss Xradia Versa. By combining the tomographic imaging capabilities of the Zeiss and the mechanical testing abilities of the Mark 10, we can get a unique glimpse into the mechanical properties of a 3D-printed sample as well as the structure responsible for those properties and the process that produced that structure.

The Mark 10 electromechanical load frame is a small, benchtop load frame that is easily configurable for tensile, compressive and bending testing of samples. It is well suited to characterize 3D-printed compression cylinders imaged with the Zeiss Xradia Versa. By combining the tomographic imaging capabilities of the Zeiss and the mechanical testing abilities of the Mark 10, we can get a unique glimpse into the mechanical properties of a 3D-printed sample as well as the structure responsible for those properties and the process that produced that structure.

Features:

- Force measurements up to 6.7 kN

- Load resolution down to 0.02 N

- Optical table mount for 3D DIC (digital image correlation) strain measurements

- Load cells, grips and fixtures for compression, tension and bending

MARK-10 Series TSTM-DC

The Mark-10 Series TSTM-DC is a small benchtop torsion load frame with a torque capacity of 11,500 Nmm and resolution down to 0.2 Nmm.

UltraFlex UltraHeat SM Induction Furnace

The UltraFlex induction furnace is coupled with load frames for in situ thermomechanical monotonic and fatigue testing. High-temperature mechanical property measurements are critical for aerospace applications, Ti alloys, and Ni-based superalloys, among others.

Features:

- 5 kW output with 1% adjustability at 30–200 kHz

- Temperatures up to 1200+ °C

- Custom coils for a range of specimen geometries

- Load cells, grips and fixtures for compression, tension and bending

Digital Image Correlation

Digital image correlation (DIC) is a non-contact full-field optical strain measurement technique used in conjunction with various mechanical testing techniques. Samples are speckled and a series of images is captured at a fixed frequency using high-resolution cameras synchronized with the load frame. The VIC 3D and ARAMIS software packages are used to analyze the images and compute strain measurements.

Features:

- Macroscopic and microscopic lenses for large and small sample areas, respectively

- Image resolution options between 0.5 and 10 megapixels

- Measured strain accurate to better than 100 microstrain

Extensometry

Extensometers provide high-resolution 1D strain measurements during mechanical testing. These measurements are necessary for accurate determination of material stiffness and strain-controlled testing. Special extensometers are used for internal (e.g., environmental chamber) and external (e.g., induction furnace) high-temperature testing.

Extensometers provide high-resolution 1D strain measurements during mechanical testing. These measurements are necessary for accurate determination of material stiffness and strain-controlled testing. Special extensometers are used for internal (e.g., environmental chamber) and external (e.g., induction furnace) high-temperature testing.

Epsilon internal extensometer

Epsilon external extensometer

MTS extensometer

Features:

- Gauge lengths from 3 to 50 mm

- 0.0003 mm resolution

- High-temperature capability

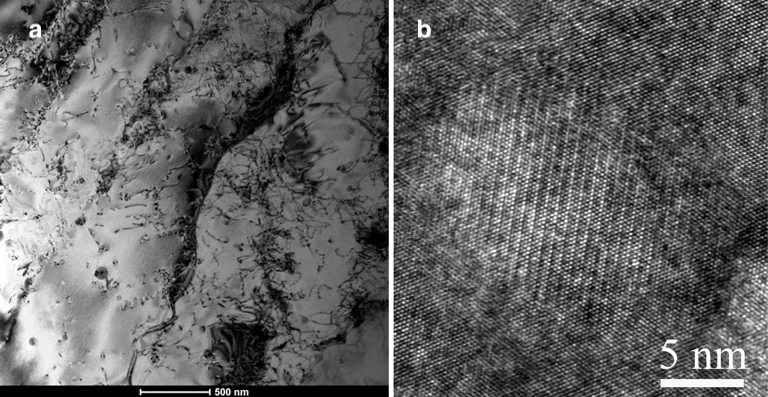

Talos F200X Field Emission S/TEM

The Talos F200X 200keV field emission scanning/transmission electron microscope is a versatile instrument for characterization of various materials. The X-FEG high-brightness electron source delivers high total current—up to five times the beam current of a standard Schottky FEG—while the integrated EDS system with four silicon drift detectors (SDDs) offers mapping capabilities of up to 105 spectra/s.

Different capabilities of TEM:

- Electron diffraction (SAED, CBED)

- Conventional transmission electron microscopy (characterization of defects in crystals)

- High-resolution transmission electron microscopy (HRTEM, point resolution 0.12 nm)

- High-angle annular dark field scanning transmission electron microscopy (HAADF-STEM, 0.19 nm lateral resolution)

- Energy dispersive X-ray analysis

a) Dislocation arrangement in 3D-printed Inconel; b) Atomic structure of a precipitate in NiTiHf alloy

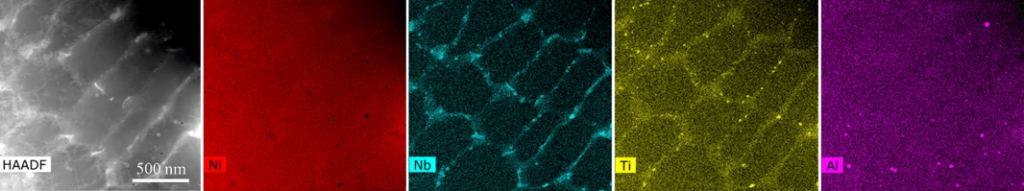

EDX chemical mapping of 3D-printed Inconel 718 using STEM/EDX technique

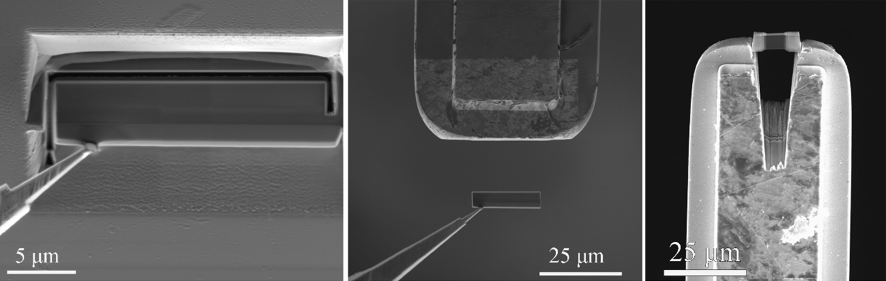

Helios Nanolab 600I Dualbeam FIB/SEM

The Helios NanoLab 600i is a versatile, high-performance DualBeam system containing a Ga+ focused ion beam (FIB) (500eV–30keV) together with a FEG extreme high-resolution scanning electron microscope (SEM) and Si-drift EDX detector for element analyses. This allows selective etching of materials while imaging the process and the area of interest at the same time with sub-nanometer resolution. In addition, the system is equipped with a gas injection system (GIS) containing a Pt source and an Omniprobe Autoprobe 200 nano-manipulator, with 10 nm positioning resolution for micro-manipulation of the specimen. This enables the Helios 600i for high-quality, site-specific TEM specimen preparation with in situ lift-out. Slice-and-view experiments can also be performed. The instrument is outfitted with an electron backscattered diffraction (EBSD) system, which allows for crystallographic determination on the nanoscale, and, along with imaging capabilities, 3D reconstructions of the material composition and crystallography.

The Helios NanoLab 600i is a versatile, high-performance DualBeam system containing a Ga+ focused ion beam (FIB) (500eV–30keV) together with a FEG extreme high-resolution scanning electron microscope (SEM) and Si-drift EDX detector for element analyses. This allows selective etching of materials while imaging the process and the area of interest at the same time with sub-nanometer resolution. In addition, the system is equipped with a gas injection system (GIS) containing a Pt source and an Omniprobe Autoprobe 200 nano-manipulator, with 10 nm positioning resolution for micro-manipulation of the specimen. This enables the Helios 600i for high-quality, site-specific TEM specimen preparation with in situ lift-out. Slice-and-view experiments can also be performed. The instrument is outfitted with an electron backscattered diffraction (EBSD) system, which allows for crystallographic determination on the nanoscale, and, along with imaging capabilities, 3D reconstructions of the material composition and crystallography.

FIB lift-out procedure for TEM sample preparation

BSE image (left) and EBSD map (right) of 3D-printed Inconel 718

Zeiss Versa X-ray Microscope

The Zeiss Xradia Versa 3D X-ray microscope enables cutting-edge, nondestructive tomographic imaging and grain reconstruction. X-ray tomography (μ-XCT) allows for the collection of both surface and internal renderings, which are used to distinguish between phases and identify defects such as porosity. Nondestructive diffraction contrast tomography (DCT) provides direct 3D crystallographic grain reconstructions for crystalline materials. Our lab offers the unique ability to first nondestructively characterize pore distributions in sample parts using the Zeiss Xradia Versa, then to mechanically test those same parts using the load frames described below to correlate defect structures and mechanical behavior.

The Zeiss Xradia Versa 3D X-ray microscope enables cutting-edge, nondestructive tomographic imaging and grain reconstruction. X-ray tomography (μ-XCT) allows for the collection of both surface and internal renderings, which are used to distinguish between phases and identify defects such as porosity. Nondestructive diffraction contrast tomography (DCT) provides direct 3D crystallographic grain reconstructions for crystalline materials. Our lab offers the unique ability to first nondestructively characterize pore distributions in sample parts using the Zeiss Xradia Versa, then to mechanically test those same parts using the load frames described below to correlate defect structures and mechanical behavior.

Features:

- Absorption contrast tomography: resolution to 0.7 µm; up to 160 kV to probe metallic samples up to 4 mm in diameter; automated center shift and reconstruction; automated ring artifact elimination

- Phase contrast tomography: improved resolution at phase boundaries to distinguish particle dispersions

- Dual-energy tomography: low- and high-energy scans allow for segmentation based on differential X-ray absorption

- Diffraction contrast tomography: grain mapping provides crystallographic orientation of samples; grain size approximation enables the preparation of samples for synchrotron experiments

Malvern Panalytical Empyrean X-ray Diffractometer

The Malvern Panalytical Empyrean X-ray diffractometer provides crystallographic and compositional information critical to understanding part mechanical performance. Through small- and wide-angle X-ray scattering (SAXS/WAXS), the ability to test samples at temperatures ranging from −200 °C to 1100 °C, and the capture of information on texture, residual stress and pair distribution functions, the Panalytical Empyrean demonstrates how the crystal structure of 3D-printed metals changes during operation at high and low temperatures, a significant concern in aerospace. Residual stress and texture are major concerns in as-printed metals and affect both structural conformity and mechanical behavior. Along with the crystallographic information that X-ray diffraction provides, compositional variations in additively manufactured parts are often far from the equilibrium phases predicted in phase diagrams. The properties of phases found in the as-printed part, and the change in those properties as those phases transform in service, is crucial information when designing for AM.

The Malvern Panalytical Empyrean X-ray diffractometer provides crystallographic and compositional information critical to understanding part mechanical performance. Through small- and wide-angle X-ray scattering (SAXS/WAXS), the ability to test samples at temperatures ranging from −200 °C to 1100 °C, and the capture of information on texture, residual stress and pair distribution functions, the Panalytical Empyrean demonstrates how the crystal structure of 3D-printed metals changes during operation at high and low temperatures, a significant concern in aerospace. Residual stress and texture are major concerns in as-printed metals and affect both structural conformity and mechanical behavior. Along with the crystallographic information that X-ray diffraction provides, compositional variations in additively manufactured parts are often far from the equilibrium phases predicted in phase diagrams. The properties of phases found in the as-printed part, and the change in those properties as those phases transform in service, is crucial information when designing for AM.

Features:

- Cu and Mo radiation for low- and high-energy XRD

- Reflection/transmission geometry with rotating sample for improved statistics

- Spinning capillary

- Bragg–Brentano optics and focusing geometry

- Residual strain measurements

- Cu/Mo focusing mirror and monocapillary 100 µm beam for microdiffraction

- 5-axis Eulerian cradle for texture mapping

- SAXS/WAXS

- Grazing incidence XRD

- Pair distribution function

- Galipix 3D area detector

- In situ stages from −200 to 1100 °C (−328 to 2012 °F)

TOF-SIMS

Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS) is a highly surface-sensitive analytical technique used to obtain elemental, isotopic and molecular information from the surface of solid materials. The surface of interest is bombarded with a pulsed ion beam that is rastered across the sample, causing a cascading collision effect that ejects material such as ions (positive, negative neutral), photons and electrons. For TOF-SIMS, we are only interested in collecting and measuring the positively and negatively charged ions that are ejected from the surface. These are considered “secondary” ions. The secondary ions are extracted from the surface and accelerated toward a highly sophisticated and specialized detector (mass spectrometer). The time it takes for those ions from when they leave the surface until they hit the detector tells us their mass (time-of-flight).

Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS) is a highly surface-sensitive analytical technique used to obtain elemental, isotopic and molecular information from the surface of solid materials. The surface of interest is bombarded with a pulsed ion beam that is rastered across the sample, causing a cascading collision effect that ejects material such as ions (positive, negative neutral), photons and electrons. For TOF-SIMS, we are only interested in collecting and measuring the positively and negatively charged ions that are ejected from the surface. These are considered “secondary” ions. The secondary ions are extracted from the surface and accelerated toward a highly sophisticated and specialized detector (mass spectrometer). The time it takes for those ions from when they leave the surface until they hit the detector tells us their mass (time-of-flight).

Each point of impact on the sample from the primary ion beam contains the entire mass spectrum as well as the X, Y and Z coordinates of that point of impact. With this information, we can create detailed ion images of the distribution of any species of interest on our sample, both in 2D and in 3D (in depth profile mode).

Features

-

Argon gas cluster source – provides the ability to detect high mass polymers and depth profile through complex organic materials

-

In situ focused ion beam – can analyze extremely rough samples, samples with voids, or samples that exhibit strong local variations in density

-

Extended dynamic range analyzer – extends dynamic range up to 7 orders of magnitude, allowing for simultaneous detection of normally saturated matrix species and trace species

-

Hermetically sealed transfer vessel – provides the ability to analyze atmospheric- or moisture-sensitive samples

Mass Spectra

2D Ion Images

3D Ion Images

FIB Tomography Ion Images

Keyence VHX-5000 Optical Microscope

The Keyence VHX-5000 Optical Microscope optical microscopy is a cornerstone of metallurgical materials analysis. The advanced image processing capabilities of the Keyence VHX-5000 enable 3D surface reconstruction. When combined with metallurgical analysis, the library of 1D and 2D measurement tools can be used to quantify phases, voids and other structural features. Differential interference contrast and polarized light microscopy expose features in polished and etched metallurgical samples that reveal details about grain growth, microstructural evolution and compositional segregation

Features:

- 20–5000X magnification

- Bright field and dark field lighting configuration

- Polarized/cross-polarized lighting

- Differential image contrast

- 50 frame-per-second image processing to produce an infinite depth of field, even at high magnifications

- 2D stitching to image large areas at high resolution

- 3D stitching to measure height profiles across large areas

- Semiautomated grain segmentation, grain shape and grain statistics

- Profilometry measurements

Shining 3D Einscan Pro 2X

The Shining 3D Einscan Pro 2X is a handheld 3D scanner that generates full-color digital files, which can be easily imported into commercial CAD software or directly to a printer. The Geomagic software can perform feature recognition and create solid files. The scan is 30 fps with 50,000 points per frame, and accuracy of 0.04 mm.